Mechanical Shaft SealsThe term Shaft Seals is used often and often misused. Technically anything that is sealing a shaft, be it an O-ring, a lip seal, braided packing, or a mechanical face seal can all be called a shaft seal. So let's discuss just how each of these is used. Let's start with the simplest first.

Lip seals often called radial lip seals or even "mechanical seals" (which is a bit confusing for reasons I will point out later), are probably the most common form of lip seal. On the positive side they are relatively inexpensive, and occupy minimal space. They do not however hold very high pressures. This form of lip seal is typical in automotive applications, sealing bearings on any type of equipment, and in some valves and pumps. However the pressure limitation keeps them out of many valves and pumps. |

|

O-Rings are often used to seal the shaft or stem in a valve and are very effective at it. The reason they can be used for this application is simply because the movement is minimal, and slow. Most valves be them gate, globe, or ball valves turn minimally (in the case of a quarter turn ball valve), and then it in the open or closed position for extended periods of time. This is the easiest way to seal a shaft.

Braided Packing also called compression packing or just pump or valve packing. Braided packing comes in many forms and is generally used to seal centrifugal pump shafts, reciprocating pump shafts (or plungers) and Valve shafts. Braided packing while it does leak (the amount of which varies with the material of choice) will hold a couple hundred PSI where most lip seals are good for about 15 PSI. With the wide range in materials braided packing can be used as a shaft seal in a wide range of applications.

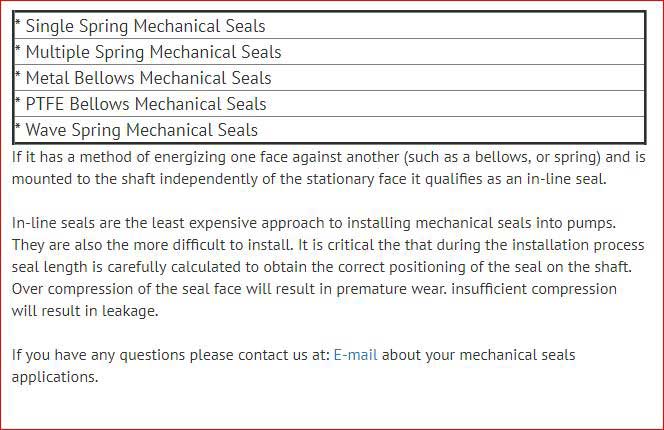

Mechanical Face Seals Often referred to as "mechanical Seals" (which is why lip seals manufacturers using the term mechanical seals can be confusing), are the most efficient method of sealing a shaft. Mechanical Seals can handle 200 to 400 PSI (in common configurations) and leak far less (only a vapor) than braided packing or lip seals. Mechanical Face shaft seals do however take more space than a lip seal, and are more expensive than lip seals, braided packing or of course O-rings. "Mechanical face seal" shaft seals can be custom engineered for high pressure and dry running services.

When you consider the three categories above, the many different designs in each category and the long list of materials that can be used in each, it's not hard to realize there are thousands of varies types and configurations of shaft seals. Knowing what is best for your application can make the difference between busting your budget, or a leaky seal. For assistance we are always available for recommendations based on your shaft seal application. Contact American Seal & Packing at: www.aspseal.com or 888-654-SEAL. |

|

|

Let us know how we can serve you better, what you would like to see, or how you feel we can improve our site. Your input is appreciated.

© 2018 Mechanicalseals.net. All Rights Reserved.